Power Semiconductors: The Backbone of Next - Generation EV Powertrain Innovations

In the global pursuit of sustainable and efficient transportation, electric vehicles (EVs) have emerged as a frontrunner. As the automotive industry undergoes a profound transformation towards electrification, power semiconductors have become an indispensable component at the heart of next - generation EV powertrain systems. These unassuming yet powerful components play a pivotal role in enabling the efficient conversion, control, and management of electrical energy, which is crucial for the performance, range, and overall viability of EVs.

1. Understanding Power Semiconductors

1.1 Basics of Power Semiconductors

Power semiconductors are electronic components that can handle high - voltage and high - current applications. They are designed to control and convert electrical power, making them essential for a wide range of applications, from industrial machinery to consumer electronics. In the context of EVs, power semiconductors are used to manage the flow of electricity between the battery, electric motor, and other components in the powertrain system.

The most common types of power semiconductors include diodes, transistors, and thyristors. Diodes allow current to flow in one direction only, acting as a kind of electrical "check - valve." Transistors, such as metal - oxide - semiconductor field - effect transistors (MOSFETs) and insulated - gate bipolar transistors (IGBTs), are used for switching and amplifying electrical signals. Thyristors are four - layer semiconductor devices that can be used for power control and rectification.

1.2 Traditional vs. New - Generation Power Semiconductors

Traditional power semiconductors, such as silicon - based IGBTs, have been the workhorses of the power electronics industry for decades. They have been widely used in EVs due to their relatively low cost and well - understood technology. However, as the demand for more efficient and high - performance EVs grows, new - generation power semiconductors are emerging.

Wide - bandgap (WBG) semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are gaining significant traction. SiC, for example, has a wider bandgap, higher breakdown electric field, and better thermal conductivity compared to silicon. This allows SiC - based power semiconductors to operate at higher voltages, frequencies, and temperatures with lower losses. GaN also offers advantages such as high electron mobility and fast switching speeds, making it suitable for high - frequency applications in EVs.

2.1 Inverter Function

The inverter is a key component in an EV powertrain, and power semiconductors are at its core. The inverter's main function is to convert the direct - current (DC) power stored in the battery into alternating - current (AC) power that can drive the electric motor. Power semiconductors, typically IGBTs or SiC MOSFETs, are used as switches in the inverter circuit.

During the operation of the inverter, the power semiconductors rapidly switch on and off to create a pulse - width - modulated (PWM) signal. This PWM signal is then filtered to produce a smooth AC voltage that can control the speed and torque of the electric motor. The efficiency of the power semiconductors in the inverter directly affects the overall efficiency of the powertrain. For example, a more efficient power semiconductor can reduce the energy losses during the DC - to - AC conversion process, which in turn improves the range of the EV.

2.2 Battery Management System (BMS)

Power semiconductors also play a vital role in the BMS of an EV. The BMS is responsible for monitoring, controlling, and protecting the battery pack. It ensures that the battery is charged and discharged safely and efficiently.

Power semiconductors are used in the BMS for functions such as voltage regulation, current sensing, and battery balancing. For instance, MOSFETs can be used as switches to control the charging and discharging currents of individual battery cells. By accurately controlling the current flow, the BMS can prevent over - charging or over - discharging of the battery cells, which can extend the battery's lifespan and improve its performance.

2.3 DC - DC Converters

DC - DC converters are another area where power semiconductors are essential. These converters are used to step - down or step - up the voltage levels within the EV's electrical system. For example, the high - voltage battery in an EV needs to provide power to various low - voltage components such as the vehicle's electronics, lights, and auxiliary systems.

Power semiconductors, such as buck and boost converters made from MOSFETs or other semiconductor devices, are used to efficiently convert the high - voltage DC power from the battery to the appropriate low - voltage levels required by these components. The efficiency of the DC - DC converters, which is closely related to the performance of the power semiconductors, impacts the overall power consumption of the vehicle and the availability of power for the main traction system.

3. How Power Semiconductors Drive EV Powertrain Innovations

3.1 Improving Efficiency and Range

One of the most significant ways power semiconductors contribute to EV powertrain innovations is by improving the overall efficiency of the system. As mentioned earlier, new - generation wide - bandgap semiconductors like SiC and GaN can operate with lower losses compared to traditional silicon - based semiconductors.

In an EV, reducing power losses in the powertrain components means that more of the energy stored in the battery can be used to drive the vehicle. This directly translates to an increase in the vehicle's range. For example, a study showed that by replacing silicon - based IGBTs with SiC MOSFETs in the inverter of an EV, the power losses could be reduced by up to 50%. This reduction in losses can lead to an increase in the driving range of the EV by 10 - 20% without increasing the battery capacity.

3.2 Enabling Faster Charging

Power semiconductors also play a crucial role in enabling faster charging of EVs. Fast - charging technology requires high - power handling capabilities and efficient power conversion. SiC - based power semiconductors are particularly well - suited for this application.

In a fast - charging station, SiC - based power modules can handle the high - voltage and high - current requirements more efficiently than traditional silicon - based components. They can reduce the power losses during the charging process, which not only speeds up the charging time but also reduces the heat generated. This is important because excessive heat can degrade the battery's performance and lifespan. With the use of advanced power semiconductors, it is now possible to charge an EV to 80% capacity in as little as 30 minutes, making EVs more convenient for long - distance travel.

3.3 Enhancing Power Density

Another area of innovation driven by power semiconductors is the enhancement of power density in EV powertrains. Power density refers to the amount of power that can be delivered per unit volume or weight of a component.

Wide - bandgap semiconductors, with their ability to operate at higher frequencies and voltages, allow for the design of smaller and lighter power electronics components. For example, SiC - based inverters can be made more compact and lightweight compared to their silicon - based counterparts. This reduction in size and weight not only improves the packaging efficiency of the powertrain but also contributes to the overall weight reduction of the vehicle. A lighter vehicle requires less energy to move, further improving its efficiency and performance.

4. Challenges and Solutions in the Adoption of Power Semiconductors in EVs

4.1 Cost Challenges

One of the main challenges in the widespread adoption of new - generation power semiconductors, especially wide - bandgap semiconductors, in EVs is the cost. Currently, SiC and GaN semiconductors are more expensive to produce compared to traditional silicon - based semiconductors. This is due to factors such as the high cost of raw materials, complex manufacturing processes, and lower production volumes.

However, as the demand for these semiconductors in the EV market grows, economies of scale are expected to drive down the costs. Additionally, continuous research and development efforts are focused on improving the manufacturing processes to reduce the production costs. For example, new techniques for growing SiC wafers are being developed to increase the yield and reduce the defect rate, which will ultimately lead to cost savings.

4.2 Thermal Management

Power semiconductors generate heat during operation, and effective thermal management is crucial to ensure their reliable performance. This is especially important in high - power applications such as EV powertrains.

As the power density of power semiconductors increases, the heat dissipation requirements also become more demanding. To address this challenge, advanced thermal management techniques are being developed. These include the use of better heat sinks, liquid - cooling systems, and new thermal interface materials. For example, some EV manufacturers are using direct - liquid - cooled power modules, where a coolant is circulated directly around the power semiconductors to remove the heat more effectively.

4.3 Compatibility and Standardization

With the emergence of new - generation power semiconductors, there are also challenges related to compatibility and standardization. Different types of power semiconductors may have different electrical characteristics and packaging requirements, which can pose challenges for EV manufacturers in terms of integrating these components into their powertrain systems.

To address this, industry efforts are underway to develop standards for power semiconductors in EV applications. These standards will help ensure compatibility between different components and make it easier for manufacturers to design and produce EV powertrains. Additionally, semiconductor manufacturers are working on developing modular and flexible power electronics solutions that can be easily integrated into different EV platforms.

5. The Future Outlook for Power Semiconductors in EV Powertrains

5.1 Technological Advancements

Looking ahead, we can expect to see continued technological advancements in power semiconductor technology. Research is ongoing to develop even more efficient and powerful semiconductors. For example, there are efforts to develop new materials and device structures that can further improve the performance of power semiconductors.

One area of focus is the development of hybrid semiconductor devices that combine the advantages of different materials. For instance, researchers are exploring the integration of SiC and GaN to create devices with the best of both worlds, such as high - voltage handling capabilities and fast switching speeds.

5.2 Market Growth

The market for power semiconductors in EVs is expected to experience significant growth in the coming years. As the global demand for EVs continues to rise, driven by factors such as government incentives, environmental concerns, and improving technology, the demand for high - performance power semiconductors will also increase.

According to market research reports, the power semiconductor market for EVs is projected to grow at a compound annual growth rate (CAGR) of over 20% in the next decade. This growth will not only benefit semiconductor manufacturers but also drive innovation in the EV industry as a whole.

5.3 Impact on the Automotive Industry

The continued development and adoption of power semiconductors in EV powertrains will have a profound impact on the automotive industry. It will enable the production of more efficient, longer - range, and faster - charging EVs, which will make them more competitive with traditional internal combustion engine vehicles.

Moreover, the use of advanced power semiconductors will also open up new possibilities for the design and functionality of EVs. For example, it may enable the development of more advanced vehicle electrification systems, such as all - electric four - wheel - drive systems and vehicle - to - grid (V2G) technology, where EVs can feed electricity back into the grid.

Power semiconductors are indeed the backbone of next - generation EV powertrain innovations. Their ability to efficiently manage electrical power is crucial for the performance, efficiency, and range of EVs. Despite the challenges in cost, thermal management, and standardization, the future looks bright for power semiconductors in the EV market. As technology continues to advance and the market grows, we can expect to see even more significant improvements in EV powertrain systems, driving the widespread adoption of electric vehicles and contributing to a more sustainable transportation future.

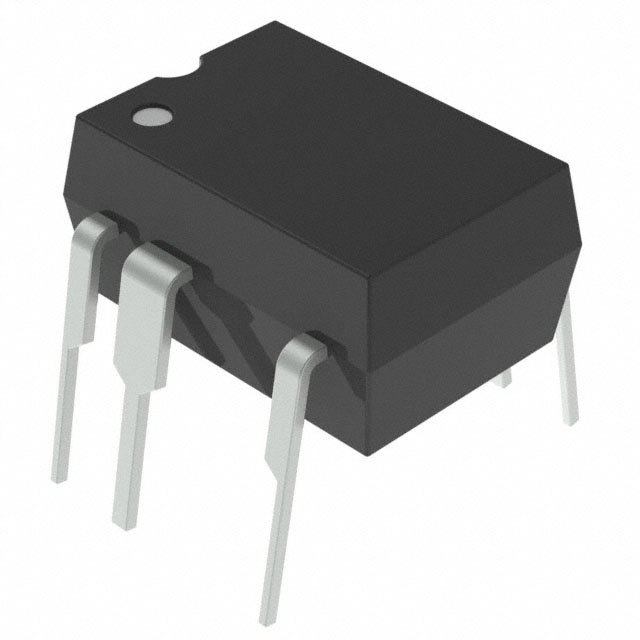

Related information

-

LNK304DN-TL Power Integrations

-

LNK304GN-TL Power Integrations

-

LNK304DG-TL Power Integrations

-

TNY277PN Power Integrations

-

TNY276PN Power Integrations

-

TNY278PN Power Integrations

-

TNY278GN-TL Power Integrations

-

TNY280GN-TL Power Integrations

-

TOP266KG-TL Power Integrations

-

TOP258PN Power Integrations

-

TOP253PN Power Integrations

-

TOP253PNAU Power Integrations